Kiln Log

Kiln Log

Second Firing .... April 3rd, 2000

Kiln Log

Kiln Log

Second Firing .... April 3rd, 2000

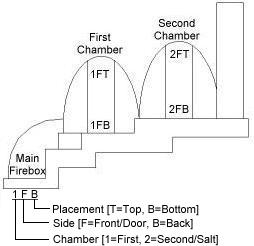

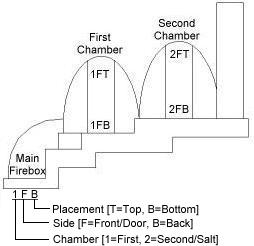

Cone Pack

<11

<10

<9

<8

>5

>3

>01

>06

Hours into Firing Notes Prep Start 1/2 1 1-1/2 2-1/2 3-3/4 4-1/2 5 5-1/2 6 7-1/2 8 8-1/2 8-3/4 9 9-1/2 10 10-3/4 12-1/2 13-1/2 14-1/2 15 16-1/2 17 17-1/2 18 18-1/2

Candle over night with propane. All main firebox air holes closed except for space for propane

nozzle. Active damper 1/2 open, passive dampers open.

05:30AM Warm night, low 40's. Clear with no wind. No pyro installed upon arrival at kiln = no

temp reading. Started fire one of main firebox air intakes using ceremonial chop sticks.

Firebox eating 2x4 pieces of construction lumber. Installed pyro in first chamber top front

(1FT) peep and read 400 degrees (F)..

Pyro at 550. Nice flame path, just kissing first chamber bag wall.

Pyro at 800. At this point mud the doors. Fluffing main firebox ashes frequently, this sends

ash sparks visible all the way to second chamber firebox stoke hole.

Pyro at 1025. Color in 1FT peep. Slow down stoking slightly.

Pyro at 1100. Dull red 1FB. Ahead of 1st firing, decided to slow down some more so as not to

over drive and get serious temperature imbalance last first firing.

Pyro at 1125. Start stoke side ports of main firebox.

Pyro at 1250.

Pyro at 1275. 1FB peep is dull red.

Main firebox front air intakes reduced/closed so that only the two center ports are 1/2 open

each. Right front of kiln has been drawing more air than left/back. First chamber is packed tighter in the back

than in the front.

Pyro at 1675. Begin to stoke first chamber side stoke. Alternate first chamber and main firebox.

Pyro at 1800. 1FB= 06 soft.

Pyro removed. 1FT=01 @ 3 o'clock. 1FB= 06 down. Decide to stoke back side of first chamber only

till 06 is down in back.

Close passive dampers all the way. Open active damper 1-2". Stoke pattern 2 into first

chamber and 1 into main firebox.

Appears we are into same issue as first firing (uneven heating). Decide to recent changes settle

in.

1FT= 3 down, 1FB= 01 down. Close active dampers back into original 1/2 open position.

1FT= 5 down, 1FB=3 down, 1BB= 3 down. Start second chamber stoking. Alternate between stoke

first and second chambers. Weather is now breezy and warm

1FT= 8 softening, 2FT= 06 down, 2FB=06 softening, 2BT= 06 down, 2BB= no movement.

1FT= 9 @ 3 o'clock, 1BB= 8 @ 3 o'clock. First chamber about one cone difference top to bottom.

Second chamber hotter on back wall (like first). Adjusted active dampers so that the one towards

back wall goes in (1-2") and one near front/door side comes out (1-2").

2BT=3 soft, 2FT=3 soft, 2BT=5 down, 2FT= 8 softening.

Start to spray a mixture of bicarbonate of soda (baking soda) and water. We used about three

pounds of baking soda mixed into a large pressurized garden sprayer to produce the sodium vapor.

1FT=10 soft, 1FB=9 down, 1BT=9 down. 2BT=9 soft, 2BB=cold!, 2FT=10 soft

1BB=10 soft, 1FT= 10 soft, 1FB= 10 soft, 2FT= 10 soft, 2FB= 9 soft, 2BB= 8 stand, 2BT= 9 soft.

1BB= 11 soft, 1FT= 10 @ 1 o'clock, 1FB= 10 soft, 2BB=8 stand, 2BT=9 @ 2o'clock, 2FB= 9 stand,

2FT= 9 soft.

Mud first chamber stoke holes. 2FT= 10 soft, 2FB= 9 down, 2BT= 9 softening, 2BB= 8 stand. We

have major cool spot in lower/back part of second chamber. Not much movement in last few hours, so we decide to

go another 1/2 hour to midnight.

Finish because we have used up all the wood! Mud up all openings and call it quits ...